|

It can be argued that the most frustrating aspect of contact lens practice isn’t determining the fit or the power, but rather dealing with a non-wetting lens—it decreases clarity and comfort and affects a patient’s overall lens wearing experience. Silicone-based materials are inherently hydrophobic, so any exposed silicone in a lens has the potential to be non-wetting. Additionally, in some patients, excessive lipids in the tear film may deposit onto the lens to create a foggy, hydrophobic surface. This issue can be reduced by dispensing low-silicone-content contact lenses; however, such lenses also impede oxygen transmission, increasing the chance for corneal complications. Other solutions include switching lid hygiene regimens and the most common method, treating the lens with plasma.

A Newcomer

Hydra-PEG (Ocular Dynamics) is a polyethylene glycol (PEG)-based polymer mixture that is covalently (permanently) bonded to the surface of the contact lens, effectively creating a wetting surface on the underlying lens material and separating it from the ocular surface and tear film. PEG has been used in ocular lubricants for decades and is known to improve lens surface wettability, which improves tear breakup time, increases lubricity and reduces protein and lipid deposition. Hydra-PEG can be applied to hydrogel, silicone hydrogel or GP lenses.

| |

| |

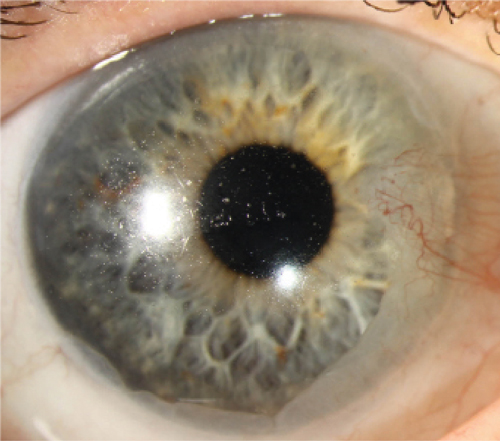

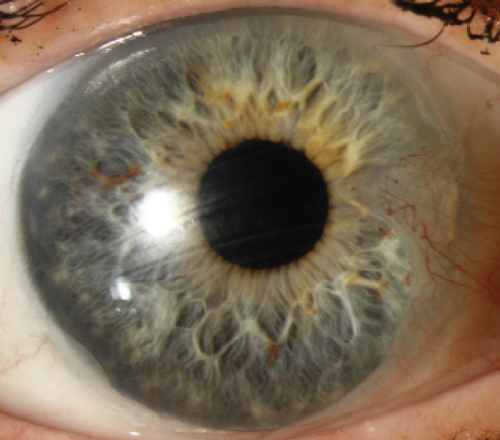

| Before (top) and after (bottom) Hydra-PEG treatment. |

During application, the first step of lens surface preparation is either the addition of a functional activator to the monomer mix or a short plasma surface treatment. Once active, the lenses are then soaked in the Hydra-PEG polymers during the extraction/hydration step, or the Hydra-PEG polymers are added to the blister pack during the autoclave process.2 In either case, once the active lens is placed in the PEG polymers, the Hydra-PEG permanently bonds to the lens surface.

In ex-vivo tests, Hydra-PEG was shown to improve wettability, surface water retention, lubricity and deposit resistance.3-6 These lens surface properties have been correlated with contact lens comfort in a number of studies.7 When applied to the Acuvue Oasys lens in a randomized controlled trial, Hydra-PEG surfaced lenses demonstrated good comfort in patients suffering from contact lens-induced dry eye.8

Note: although it is a permanent coating, Hydra-PEG has only been tested out to three months of simulated rubbing/cleaning cycles. Ocular Dynamics currently recommends hydrogen peroxide-based cleaners, but reports it is also in the process of testing multipurpose solutions for compatibility.

Thus far, my clinic experience with this product has been positive: I have found it creates a wettable, clear and comfortable surface, even in the most challenging of conditions, such as lagophthalmos and significant ocular surface disease. I anticipate Hydra-PEG will provide another useful option in most contact lens practices.

1. William Hoffman. Personal communication. 2008.

2. Ocular Dynamics. Hydra-PEG Manufacturing. Available at: www.oculardynamics.com/#!manufacturing/c11sc. Accessed March 25, 2015.

3. Measured via Captive Bubble Contact Angle. Ocular Dynamics data on file, 2014

4. Measured via Water Breakup Time. Ocular Dynamics data on file, 2014

5. Measured via Digital Friction Evaluation. Ocular Dynamics data on file, 2014

6. Measured via Radiolabeled Lysozyme Deposition Assay. Ocular Dynamics data on file, 2014

7. Jones, L. et al. “The TFOS International Workshop on Contact Lens Discomfort: Report of the Contact Lens Materials, Design, and Care Subcommittee”. IOVS, October 2013, Vol. 54

8. Caroline, P. “Hydra-PEG: A Solution to Contact Lens Discomfort?” Poster presented at Global Specialty Lens Symposium 2015.