|

Earlier this year, I started working part-time at an ophthalmology practice, mainly seeing contact lens patients. The staff looked at me with wide eyes and handed me a chart of a patient who was in the office for a “contact lens check” (as an aside, I despise that phrase). As it turns out, his simultaneous vision multifocal GP lenses were last exchanged six months ago and he was returning because he was unhappy with them.

I tried to get the back story from the electronic medical record, but I was confused. I decided to talk directly to the patient—or rather, I should say, listen. My goal was to ask questions and be attentive (this is when being an optometrist is kind of like being a coach). The patient relayed to me that he is no longer wearing the simultaneous multifocal GP lenses he was dispensed six months ago (though he brought them for me to examine and they fit perfectly, if you’re keeping score).

He proceeded to explain how he likes the “old” lens he has on his right eye. He has no lens on the OS because it’s been lost for years. I looked at the lens and saw a scratched-up, flat-fitting, translating GP lens with a lined segment that is overall moving just a bit too much and decentering laterally. But I thought to myself, translating GP multifocal aren’t that hard, so I told him we can order new translating lenses. He said he wants this exact lens and his records are in the chart. I thought to myself, “Great, I’ll reorder the same thing!” and sent him on his way with a smile.

Not So Easy

It later occurred to me that if it were that easy, the previous practitioner who fit him probably would have also duplicated the lenses he liked. In addition, the only record I found is a decades-old single paragraph letter from his (now retired) doctor’s office stating the parameters of one pair of Tangent Streak lenses. Who knows if this was the lens he had on his eye, which didn’t fit very well. And did I mention the lined Tangent Streak lens is currently temporarily out of production?

I spoke with Dede Reyes, board member of the Contact Lens Society of America and director of professional education at ABB Optical Group, who explained that the lined Tangent Streak production delay is only temporary. There is difficulty with the British-manufactured lathe, and the engineers needed to do the repair are not available to travel from England due to COVID-19 restrictions. It takes a very customized lathe to manufacture the Tangent Streak design, and labs are in somewhat of a difficult spot getting this specific lens made right now. However, practitioners should note this only impacts the lined Tangent Streak design; the “no-line” version is currently available and in production.

|

|

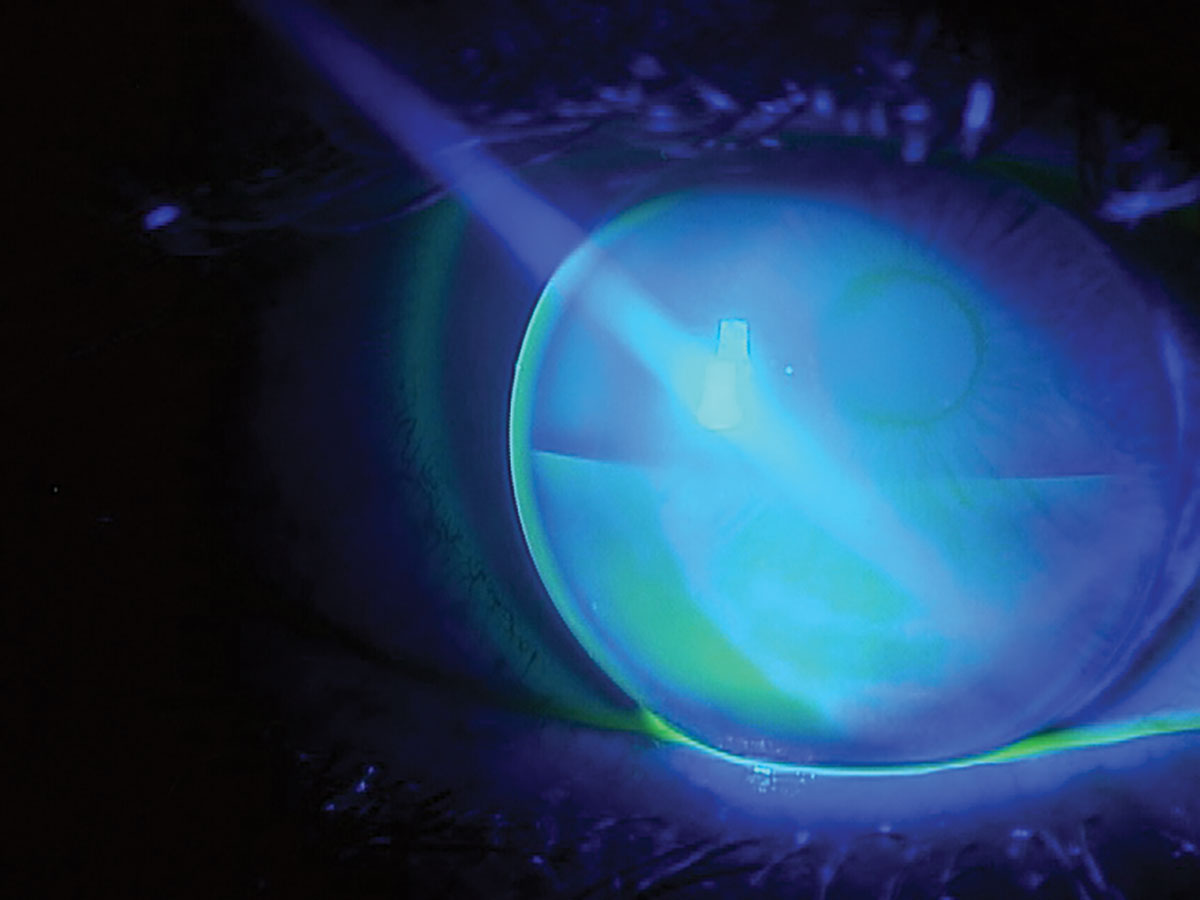

Pictured here is a Tangent Streak GP lens. Click image to enlarge. |

Not willing to risk showing up with a lens that was “unlined” for a patient who is clearly expecting this, I re-designed a segmented translating GP with new parameters in an attempt to mimic the lined Tangent Streak as closely as possible. This patient was also aware of the presence of the truncation on his previous pairs, so I had to ensure that was appropriate.

I was able to look back and see the parameters of what could have been this patient’s preferred lens in the old letter from his previous practitioner. I chose ABB Concise’s Natural Vision TC translating GP lens design and did my best to adjust the fit to improve stability and centration. Since the habitual lens had excessive movement and lateral decentration, I increased the overall diameter and prism. The new lens parameters were OD 7.58/9.6/-2.25DS and OS 7.58/9.6/-2.75DS. Both lenses were designed with a 2.50D add, 4.40mm segment height, 2.50D prism and a 0.40mm truncation. The material was Fluoroperm 30 to match his habitual lens material based on the provided note, and both lenses were blue in color.

A few things to note on the changes: typically, one would choose a 4.40mm segment height when visible sclera exists between the inferior limbus and lower eyelid. This patient did not appear to have that issue; however, I hesitated to change the seg height from his habitual lens, especially since I also made other parameter changes. The habitual lens was a 9.4mm OAD, but I decided to go slightly larger to attempt to improve the centration, although any GP expert would tell you that the 0.2mm increase I made was probably not clinically significant on its own.

Upon dispense, the patient saw my technician who placed the lenses on his eyes and relayed to me his immediate reaction—a huge smile. He could read 20/20 at distance and 20/25 at near and was elated with his vision improvement. In fact, he proudly announced that he didn’t need to see me at all and was leaving with his lenses. Of course, the technicians insisted he stay so I was able to assess the lenses, which sat on the lower lid appropriately and moved between blinks, translating as expected. The fluorescein pattern was aligned and resting on the lower lid with good upward translation on near gaze. I was much happier with the centration, and the segment was positioned at 180°. There was no over-refraction.

Had the patient not been successful in these lenses (even despite any adjustments I deemed necessary on follow-up), my next step would have been to switch back to the Tangent Streak no-line aspheric multifocal. Thankfully, he was doing well at follow-up and had no complaints.

The patient left happily with his lenses and I was able to be the hero, or at least appear that way for a day. The real heroes are the people behind the scenes who not only make the lenses, but also repair the lathes. I’ll never take those folks for granted again!